Understanding Harmonics in Steel Industries

Steel manufacturing processes involve a multitude of electrical equipment, including arc furnaces, induction motors, and rectifiers. While essential for production, these equipment generate harmonics – unwanted electrical frequencies that can disrupt power quality and lead to various issues such as voltage distortions, equipment malfunctions, and increased energy losses.

How Active Harmonic Filters can be useful in Steel Industries?

In the realm of steel production, maintaining optimal power quality is paramount to ensuring efficient operations and minimising downtime. However, the inherently dynamic and power-intensive nature of steel manufacturing processes often leads to power quality issues such as harmonic distortion, voltage fluctuations, and power factor imbalance. These issues not only compromise equipment performance but also result in increased energy consumption and operational costs. In this blog post, we’ll explore how AHFs can revolutionise the operations of steel plants, ensuring smoother production processes and significant cost savings

The Need for Active Harmonic Filters in Steel Industries

In the steel industry, where uninterrupted power supply is critical for continuous production, the presence of harmonics poses significant challenges. Active Harmonic Filters offer an effective solution by dynamically mitigating harmonics in real-time, maintaining a clean and stable power supply.

Active Harmonic Filter is an advanced power quality solutions that offer a comprehensive approach to mitigating harmonic distortion and improving energy efficiency in steel industries. Let’s delve into how AHFs can revolutionize power management in steel plants:

The significance of hybrid harmonic filters in power systems lies in their ability to offer a balanced and effective response to a wide spectrum of harmonics. Here are key aspects of their significance:

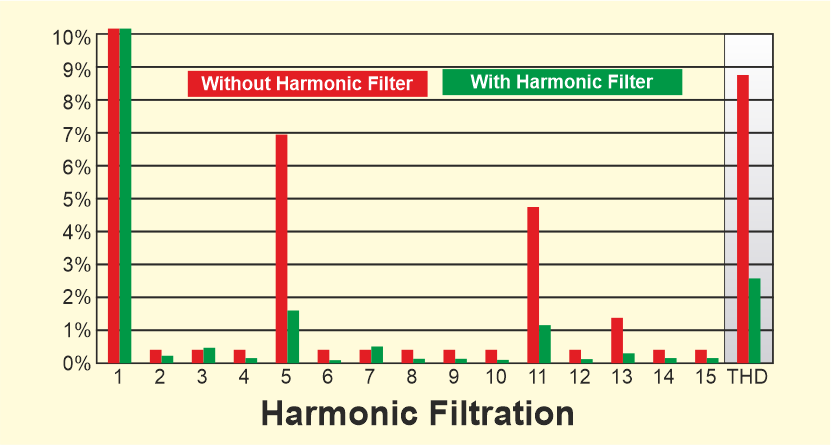

Harmonic Mitigation: Steel manufacturing processes involve a multitude of nonlinear loads such as arc furnaces, induction furnaces, and rolling mills, which generate harmonic currents and voltages. These harmonics can disrupt the power supply, leading to equipment failures and production inefficiencies. AHFs dynamically monitor the harmonic distortions in real-time and inject equal but opposite harmonics to cancel out the undesired harmonics, thus ensuring clean and stable power supply to critical equipment.

Voltage Regulation: Fluctuations in voltage levels can adversely affect the performance of sensitive equipment in steel plants, leading to production delays and quality issues. AHFs employ advanced voltage regulation techniques to stabilize voltage levels and maintain them within acceptable limits, thereby safeguarding equipment and optimizing production processes.

Power Factor Correction: Maintaining the ideal power factor consistently is essential for maximising the utilisation of electrical systems and minimising reactive power losses in steel plants. Active Harmonic Filter can actively monitor power factor variations and automatically adjust reactive power compensation to ensure optimal power factor levels, resulting in reduced electricity bills and improved energy efficiency.

Reduced Energy Consumption: By eliminating harmonic distortion, stabilizing voltage levels, and optimizing power factor, AHFs contribute to significant energy savings in steel industries. The efficient utilization of electrical power translates to lower energy consumption, reduced carbon emissions, and enhanced sustainability credentials for steel manufacturers.

Enhanced Equipment Reliability: Uninterrupted operation of critical equipment is essential for maintaining smooth production flows in steel plants. AHFs protect sensitive equipment from voltage sags, swells, and harmonic-induced overheating, thereby extending equipment lifespan, reducing downtime and minimizing maintenance cost.

Conclusion

In conclusion, Active Harmonic Filters offer a holistic solution to the power quality and energy management challenges faced by steel industries. By mitigating harmonic distortion, stabilizing voltage levels, optimizing power factor, and reducing energy consumption, AHFs empower steel manufacturers to achieve higher productivity, lower operating costs, and greater operational reliability. Embracing AHFs is not just a technological upgrade; it’s a strategic investment in the future competitiveness and sustainability of steel production.

At NAAC Energy Controls Pvt Limited (NECPL), we specialise in providing tailored Active Harmonic Filter solutions designed to meet the unique needs of steel industries. Contact us today to learn more about how AHFs can help transform your power quality and drive operational excellence.